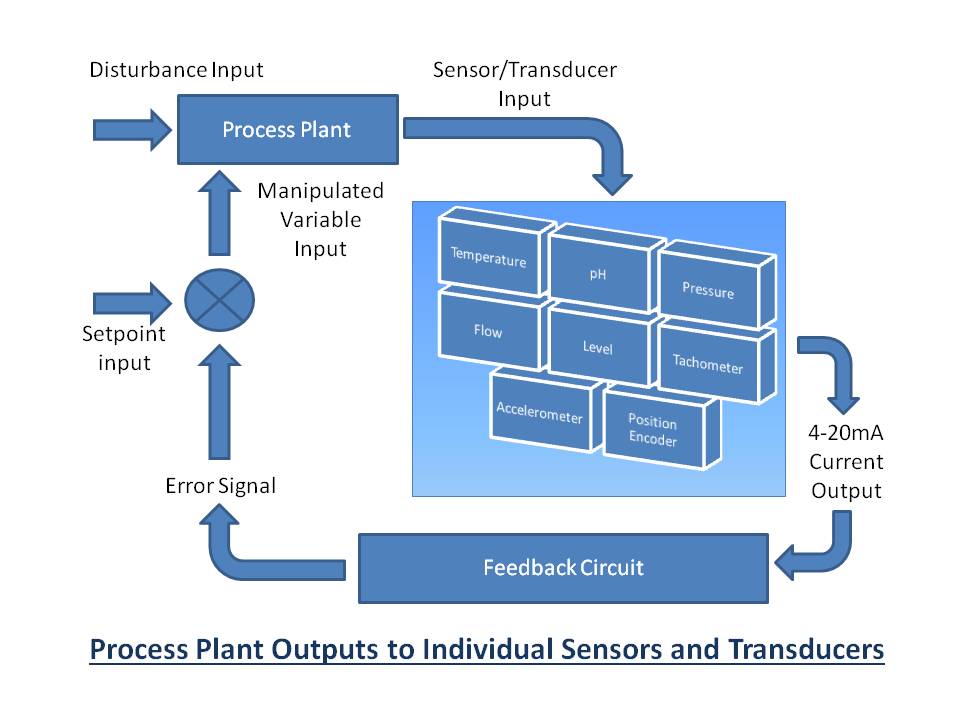

The calibration of analogue signals from myriad sensors and transducers in a process plant is essential not only to ensure correct readings on instruments but also for the feedback signals required for stable process plant operation.

A typical process plant will generate outputs to several sensors and transducers as shown in the above diagram. These outputs include process parameters like temperature, pH, pressure, flow and level, and mechanical parameters from devices like tachometers, accelerometer and position encoders, amongst others.

The output from these sensors is an analogue signal level, the majority of which is usually expressed as a 4-20mA current, although there are instances where 0-10V voltage signal may be preferred despite the disadvantage that the voltage method cannot detect a broken wire.

The 4-20mA current loop signal is handy not only for showing parameter readings on dials and gauges but also for feeding back and conditioning signals for corrective action by adjusting the setpoint value on the plant input to stabilise plant operation in accordance with the plant disturbance input.

Affordable loop calibration

However, for this signal to be trusted, it must be calibrated, and the choice of calibrator used depends on the size and complexity of the process plant. Starting at prices from just over £300, loop calibrators can be afforded by small micro breweries as well as by multinational oil and gas giants.

For example, the Extech 412400 Multifunction Process Calibrator will source 0-24mA signals with 0.01mA resolution and measure 0-50mA with 0.1mA resolution. This multifunctional calibration device can be used to measure and source current, voltage and type J, K and T type thermocouples. It features single/continuous step function for both voltage and current and a self-contained 24V loop power supply.

It is also possible to store up to five user settable output values to speed up calibration for repeat testing. The memory locations/output values can be selected manually, or the series of five values can be stepped automatically for the voltage and current functions. For the temperature function, only manual stepping is available.

Moving up the scale in terms of functionality, the Fluke 787 ProcessMeter is a combination digital multimeter and loop calibrator that will source, simulate and measure loop current with 0.05% accuracy and 1mA resolution while also measuring voltage, AC/DC current, resistance, continuity and frequency, as well as diode testing.

The meter provides steady, stepped, and ramped current output for testing 0-20mA and 4-20mA current loops. The process engineer can choose source mode, in which the meter supplies the current, or simulate mode, in which the meter regulates current in an externally-powered current loop.

Source mode is used when needed to supply current into a passive circuit such as a current loop with no loop supply. Source mode depletes the battery faster than simulate mode, so simulate mode is used where possible.

Pressure Calibrators

While the Beamex MC2-MF Multifunction Calibrator is primarily an electrical calibrator capable of correctly measuring different electrical generation and simulation techniques, it also includes an optional pressure calibration function for pressure testing equipment using the connection for external pressure modules.

It has built in pressure, electrical/temperature and electrical sections as standard. The MC2-MF also provides advanced features such as leak testing, damping, scaling, deviation, redundancy and difference measurements.

It is typically used by plant maintenance engineers and technicians at pharmaceutical plants, food and beverage plants, oil, gas and petrochemical plants and refineries, power plants and service organisations.

The Time Electronics 7050 Multifunction Process Calibrator can measure three ranges up to 40V, 400mA and 40 kilohms. It can also output voltage to 10V with one microvolt resolution, output current to 20mA with one microamp resolution and output resistance from 0-400 ohms with 0.01 ohm resolution.

As a thermocouple calibration device, it can be used in combination with type J, K, T, R, S, B, N and E thermocouples. It can also be used to simulate and measure RTD as well and the readouts are displayed automatically on the built-in screen as both input and output functions.

The 7050 also includes five calibration points which can be accessed via a preset percentage selector. This allows all functions to be generated in a fully user programmable ramp format. The unit can also be used as a signal converter and any electronic input signal can be converted and output as a proportional signal of 4-20mA, 0.5V or square root 4-20mA.

Conclusion

No two loop calibrators are alike in terms of functionality, ease of use, data capture capacity, and so on, so price is an obvious factor but so too is a thorough understanding of the intended application needs.

For more calibration equipment, please visit the multifunction calibrators page at Tester.co.uk.