Mark-10 Advanced Test Stand, Torque, Motorized (200 lbFin / 22 Nm or 100 lbFin / 11.5 Nm) - Vertical or Horizontal

- Programmable angle limits

- Digital display of angle

- TSTM-DC / TSTMH-DC models

- Independent CW and CCW Speeds

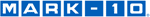

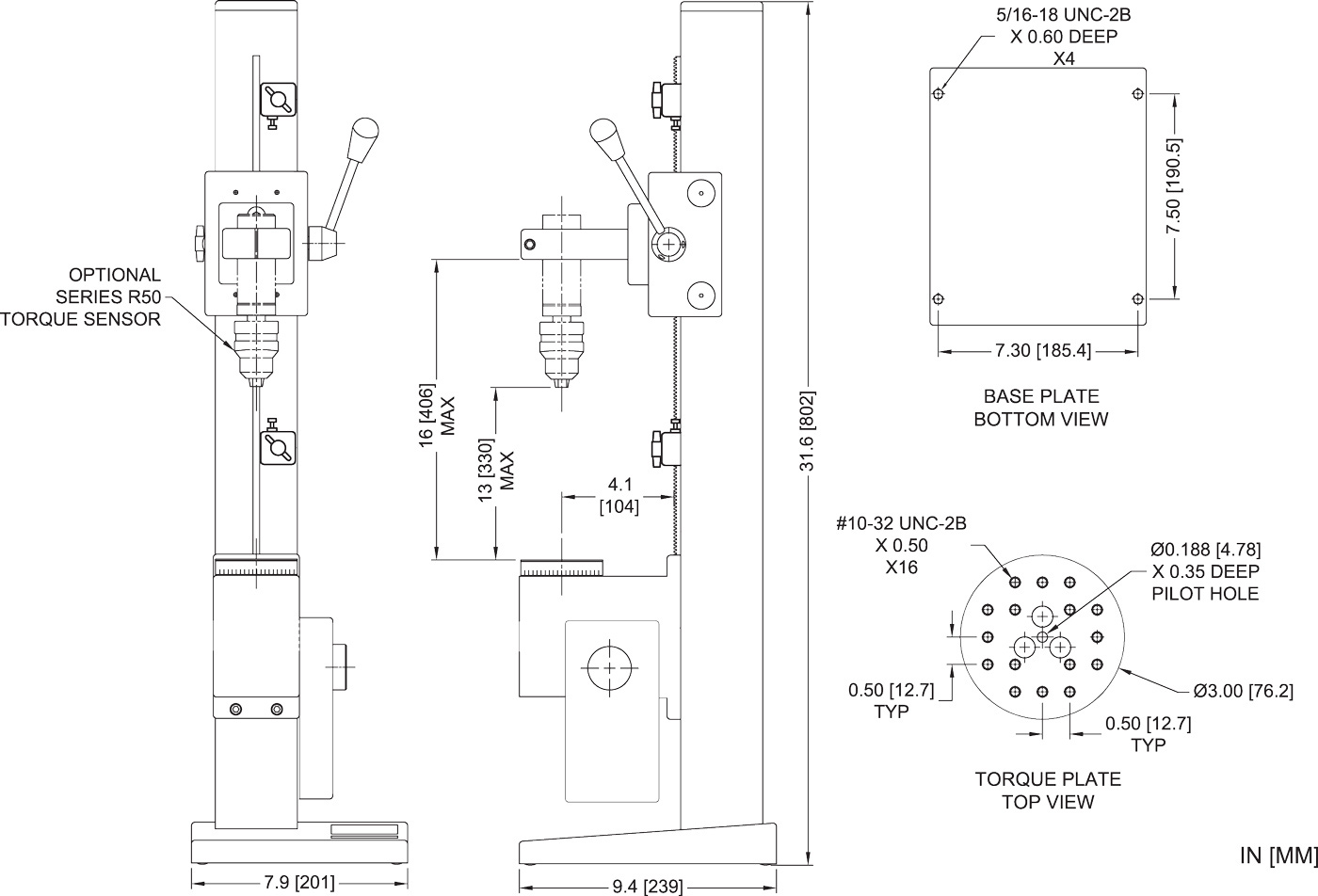

Series TSTM-DC advanced motorized torque test stands are designed for a wide variety of applications, including closure torque testing, fastener torque testing, and more. Two torque capacities are available, 100 lbFin (11.5 Nm) and 200 lbFin (22 Nm).

The stands include a torque loading plate with tapped holes for grip and fixture mounting. Stepper motor design eliminates speed variation with the load. A lever-operated slider with travel stops makes engaging and disengaging samples quick and efficient. A modular mechanical design allows the stand to be configured for a variety of applications.

The controller features an integrated angle display and output, programmable angle travel limits, PC control capability, programmable cycling, auto return, overload protection, password protection, and more.

Key Features

- Configurable clockwise and counter-clockwise speeds, RPM or °/s

- Digital angle indicator

Rotational travel is indicated in degrees or revolutions, with RS-232 output of angle data. - Angle limits

Stop at or cycle between configurable upper and lower angle limits, in degrees or revolutions. - Angle dial with 2° resolution

- Auto-return

The torque table rotates to an angle limit or torque limit (requires a Model M7I or M5I indicator and AC1108 multi-function cable), stops, and reverses direction at full speed to the other angle limit or torque set limit. - Cycling

Same as auto-return, but with the ability to program up to 100,000 cycles. Configurable dwell time for upper and lower limits (set independently) can be set up for up to 10,000 seconds. CW and CCW speeds may be set independently. - Configurable button functions

CW and CCW button presses can produce one of the following motions: (1) momentary (button-hold), (2) maintained (button release), or (3) automatic (press and hold for momentary, or quick press and release for maintained motion). - Overload protection

Protects the torque sensor against overload (requires a Model M7I or M5I indicator and AC1108 multi-function cable). - PC Control

Control the test stand with your application using a supplied library of motion control and data collection serial commands.

Note the following co-requirements:

- Password protection

Prevents unauthorized changes to settings.

What's in the Box!

- (1) DC controller

- (1) Controller connection cable

- (1) Indicator mounting kit

- (1) Encoder cable

- (1) Column cap with hardware

- (1) Allen wrench set

- (4) Thumb screw for mounting indicator

- (1) Power cord

- (1) Base with hardware (TSTM-DC)

- (2) Mounting leg with hardware (TSTMH-DC)

- (1) Additional column cap with hardware (TSTMH-DC)

Product Range

- TSTM-DC-1U Advanced Test Stand, Torque, Motorized, 200 lbFin / 22 Nm, Vertical (UK)

- TSTM-DC-2U Advanced Test Stand, Torque, Motorized, 100 lbFin / 11.5 Nm, 60 RPM Max, Vertical (UK)

- TSTMH-DC-1U Advanced Test Stand, Torque, Motorized, 200 lbFin / 22 Nm, Horizontal (UK)

- TSTMH-DC-2U Advanced Test Stand, Torque, Motorized, 100 lbFin / 11.5 Nm, 60 RPM Max, Horizontal (UK)

Call 01642 931 329 or complete the form:

| Model | Maximum Torque | Speed Range | |

|---|---|---|---|

| TSTM(H)-DC-1 | 200 lbFin [22.0 Nm] at 7.5 RPM, decreasing proportionally to 100 lbFin at 15 RPM | 0.01 - 15 RPM [0.05 - 90°/s] |

|

| TSTM(H)-DC-2 | 25 lbFin [2.8 Nm], increasing proportionally to 100 lbFin [11.5 Nm] at 15 RPM | 0.04 - 60 RPM [0.2 - 360°/s] |

|

| All Models | |||

| Speed Accuracy | ±0.2% of setting, ±0% variation with load | ||

| Rotational Travel Accuracy | ±0.7° [0.002 revolutions] | ||

| Rotational Travel Resolution | 0.1° [0.01 revolutions] | ||

| Rotational Travel Repeatability | 0.1° [0.0003 revolutions] | ||

| Throat | 4.10" [104 mm] | ||

| Manual Adjustment | 12° / adjustment knob revolution | ||

| Maximum Slider Travel | 15.5" [394 mm] | ||

| Slider Travel Rate | 1.047" [26.6 mm] / lever revolution | ||

| Universal Power Supply | 80-250 VAC | ||

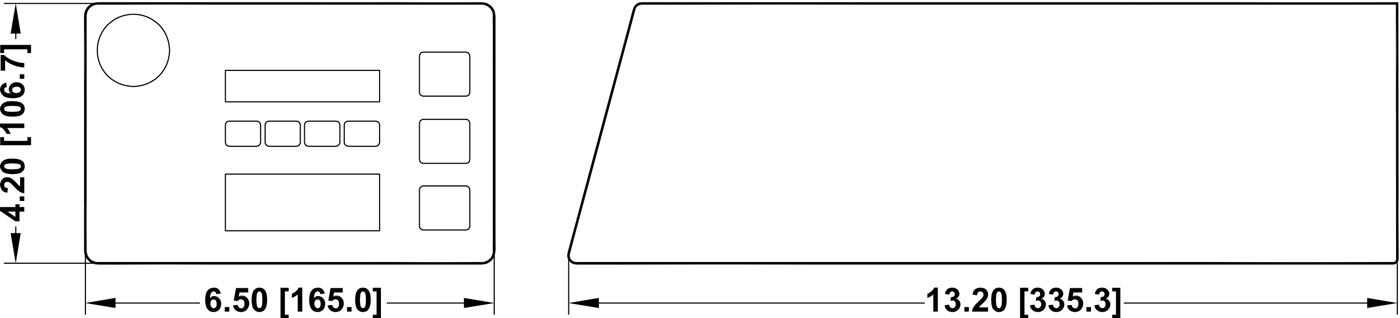

Vertical Dimensions

Horizontal Dimensions

Horizontal Dimensions