Ultrasonic Leak Detectors

A range of ultrasonic detection equipment optimised for identifying and locating gas leaks, blockages and electrical and mechanical issues. These instruments can be used to inspect switchgear, transformers, motors, gears and gearboxes, as well as pipe/ tube systems.

Find out more about Ultrasonic Leak Detectors below.

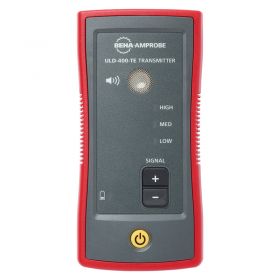

- Detect leaks in unpressurised systems and equipment

- Three signal levels for precise location of leaks

- For use with Beha-Amprobe’s ULD-500-RE Receiver

- Frequency range: 150 Hz to 7500Hz

- Amplification up to 80dB

- Four selectable digital bandpass filters

- SuperDetect technology

- Two inspection modes

- Four indoor band-pass filters

- Frequency range 150 Hz - 7500 Hz

- 7" LCD touch screen

- Find vibration, electrical discharge and leaks in pressurised and unpressurised systems and equipment

- Frequency range: 20kHz to 90kHz

- Adjustable sensitivity and filter function

- Pinpoint the source of leaks, vibration and electrical discharge

- Range: 20kHz to 90kHz

- Adjustable sensitivity and filter function

- Four kits optimised for various applications

- Detect and measure ultrasound emissions to locate leaks, blockages and faults in various systems

- Equipped with an LED bar graph: each LED light equates to 3dB

- Four kits optimised for different applications

- Check electrical, mechanical and pipe/tube systems for faults, blockages and leaks

- Can be used to detect electrical phenomena such as corona and arcing

- Tightness testing

- Leak detection

- Accessory for non-pressurised applications

- Doubles the detection range of standard scanning modules

- Five versions available, each optimised for a specific Ultraprobe® model

- Equipped with a highly sensitive, directional parabolic dish and seven transducers

- Lubricate bearings and monitor ultrasonic frequencies simultaneously

- Prevent over lubrication and associated issues

- Translates ultrasounds into an audible range and displays ultrasonic amplitude via the LED display

- Accuracy checker

- Verify the performance of the Teledyne FLIR Si124 Ultrasound Camera

- Supplied with a table tripod

- Six kits optimised for different applications

- Use ultrasonic technology to detect leaks, compressed air, faulty components and bearings, and electrical discharge

- Adjustable sensitivity for pinpointing faults

- Available in six kits optimised for various applications

- Utilise ultrasonic technology to locate leaks, blockages, faulty steam traps,etc

- Tune the detector to the problem-specific ultrasonic frequency

- Kits are optimised for various applications

- Find leaks, compressed gases, mechanical faults and electrical discharge

- Includes Ultratrend DMS Software for data logging and management

- Monitor bearing lubrication

- Converts ultrasonic signals into audible sounds

- Two digital displays

- Easy-to-use and adaptable

- Locate leaks, compressed air & mechanical and electrical failings

- Intrinsically safe: can be used in ATEX & EX areas

- Highly sensitive point-and-shoot troubleshooting ultrasonic equipment

- 64 low-noise MEMS microphones

- Adjustable bandwidth: 2 kHz to 65 kHz

- 5MP optical camera

- Two kits with different certifications

- Utilise ultrasonic technology to find compressed air/ gases, leaks, mechanical faults and electrical discharge

- Simple Spin and Click™ operating interface

- Specifically designed for cabin leak detection

- The Ultraprobe® 9000 Ultrasonic Detector features a fixed 40Hz frequency

- Supplied with a UDMTG-1991 360 Multidirectional Tone Generator

- 124 microphones

- View the leak rate (l/min or CFM) in real-time

- Auto-filtering & automatic distance input

- Utilises sound technology to identify and locates leaks

- SoundMap provides increased detail and clarity

- Identifies and isolates leak and vacuum frequencies

- Locates leaks in compressed air, gas, steam and vacuum systems

About Ultrasonic Detectors

As the name indicates, ultrasonic sensors measure distance by using ultrasonic waves. The sensor head emits an ultrasonic wave and receives the wave reflected from the target. Ultrasonic Sensors measure the distance to the target by measuring the time between the emission and reception.

They're used primarily as proximity sensors and can be found in automobile self-parking technology and anti-collision safety systems. Ultrasonic sensors are also used in robotic obstacle detection systems, as well as manufacturing technology.

An array of detectors ranging from under £1,000 to over £10,000.