Process Calibrators & Instruments

About Process Calibrators & Instruments

The process industry is assembled by any industrial company that produces a constant supply of a particular product. A good example of this is the production of oil, as the same process is applied to crude oil to produce its various components. This process is applied constantly and only very rarely changes. Process systems, therefore, have to be incredibly reliable machines as they will be running for large periods and must not fail.

Most process industries prefer using preventative maintenance to ensure the longest running times possible, this means the detection of potential issues is of the highest priority. A wide range of different tools can be used to locate any potential problems from thermal imaging cameras to multifunction testers.

When a shutdown is essential however the work must be completed as quickly and thoroughly as possible and to help achieve this the tools must be of the very highest standard.

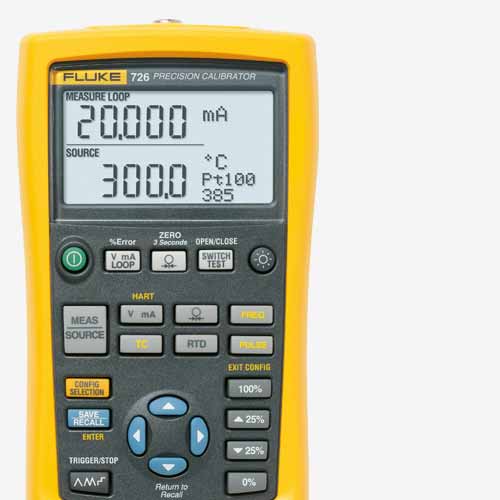

One of the major parts of the process industry is the wide range of sensors that ensure that the product is of the highest quality. To ensure correct operation all of the sensors should be regularly calibrated using the appropriate tools for the job.

Popular Products

-

Fluke 754 Documenting Process Calibrator with HART Communication: A powerful tool for calibrating HART smart transmitters and other instruments. It sources, simulates, and measures pressure, temperature, and electrical signals, making it an all-in-one solution. The built-in HART interface eliminates the need for a separate communicator, while data logging enables automatic documentation of procedures.

-

Extech PRC30 Multifunction Process Calibrator: A precise tool for sourcing and measuring various process signals, supporting eight thermocouple types, current (mA), and voltage (mV and V) devices. It features 24-volt loop power, five user-adjustable presets, and outputs in Fahrenheit, Celsius, and millivolts. Included are test leads, alligator clips, calibration cables, an AC adapter, AA batteries, and a hard case.

-

FilesThruTheAir EL-USB-3 EasyLog USB Voltage Datalogger: Measures 0 to 30V DC. Its pen-shaped design includes screw terminals for easy connections and a USB port for the PC interface. Users can configure settings via free EasyLog software, logging up to 32,510 readings at intervals from 1 second to 12 hours. It features LED indicators for alarms and is powered by a replaceable lithium battery, lasting up to one year.

-

Fluke 707 Loop Calibrator: A high-performance tool for calibrating and maintaining current loops. It offers fast calibration with push-button and knob controls, measures and simulates currents up to 24 mA with 0.015% accuracy and 0.001 mA resolution. The large display shows both mA and percentage of span, and it features selectable step and ramp outputs. With a 24V loop supply for powering transmitters.

-

Time Electronics 7005 Voltage, Current & Loop Calibrator: Handheld instrument for calibrating and simulating voltage and current loops. It sources and measures up to 50 mA and 21 V with 0.01% accuracy, supports loop current sinking and transmitter simulation and features programmable steps and ramp functions. Its compact, robust design is ideal for field use, and the internal NiMH battery provides up to nine hours of operation.

-

PanelPilot SGD 24-M 2.4” Programmable Panel Meter.: The PanelPilot SGD 24-M has a 2.4-inch TFT colour touchscreen, dual analogue inputs, and alarm outputs for various applications. Users can customize the display using the free PanelPilot M Software, creating layouts like bar graphs and trend graphs, with options for colours, text labels, and input scaling, all uploaded via USB.

-

Fluke 700MTH Premium Metric Pressure Test Hose Kit: A durable, 5,000 psi-rated accessory for connecting pressure transmitters and test pumps. It features a 1/8" NPT connection for permanent mounting and a male connector for 1/4" female metric/BSP fittings.

FAQs

-

What is a process calibrator?

A process calibrator is an instrument for field testing and calibration of industrial process equipment. It measures and sources electrical signals like voltage, current, and resistance, and simulates temperature sensors such as thermocouples and RTDs. These tools verify the performance of transmitters, sensors, and other instruments to ensure accurate operation. -

How do process calibrators work?

Process calibrators generate and measure precise electrical signals to test and calibrate industrial instruments. They source and measure voltage, current, resistance, and temperature, simulating sensor and transmitter outputs to ensure instruments operate within specified parameters. By comparing measured values with expected standards, they facilitate necessary adjustments. Multifunctional calibrators can handle various signal types. -

What are the key features to look for in a process calibrator?

When choosing a process calibrator, consider multifunctionality for sourcing and measuring signals like voltage, current, resistance, and temperature. Prioritise accuracy, precision, and a user-friendly interface with a clear display. For fieldwork, opt for a portable, durable, handheld model. Features like data logging, loop power, and automatic stepping enhance efficiency in calibration tasks. -

What are the benefits of using a process calibrator?

Using a process calibrator ensures accurate, reliable instrument performance, essential for process control and safety. Regular calibration minimizes errors, improves efficiency, and reduces downtime by preventing costly mistakes. -

What instruments are used for process calibration?

Instruments used for process calibration include multifunction calibrators, voltage and current calibrators, temperature calibrators, pressure calibrators, and loop calibrators. -

What are the benefits of using a multifunction process calibrator?

A multifunction process calibrator can handle multiple signals like current, voltage, frequency, and resistance, reducing the need for multiple devices and saving time and cost. Its advanced features, such as data logging and automated calibration, improve efficiency and accuracy. -

How do process calibrators differ from other types of calibrators?

Process calibrators handle multiple signals like voltage, current, resistance, and temperature, unlike standard calibrators designed for single signals. They often include features like data logging, loop power, and automated calibration, enhancing efficiency and ease of use. -

What is the accuracy of process calibrators?

Typically at least four times more precise than the device under test (DUT). For example, temperature calibrators may achieve accuracies around 0.1°C for certain sensors. Accuracy varies based on the signal type, calibrator model, and usage conditions. This precision is crucial for verifying and adjusting industrial instruments. -

Can process calibrators measure multiple parameters?

Yes, process calibrators can measure multiple parameters such as voltage, current, resistance, and temperature. This multifunctionality allows them to test and calibrate various process instruments efficiently, reducing the need for multiple devices. -

How do you perform a calibration using a process calibrator?

Connect it to the device under test (DUT) and set it to the desired measurement or source mode. Adjust to the specified test points, record readings from both the calibrator and the DUT, and compare them to identify discrepancies. Make necessary adjustments to the DUT, repeat for all test points, and document the results, including any adjustments and confirmations of the DUT's compliance with specified parameters.

Multifunction Calibrators

Multifunction Calibrators

Voltage & Current Dataloggers

Voltage & Current Dataloggers

Voltage, Current & Loop Calibrators

Voltage, Current & Loop Calibrators

Panel Meters

Panel Meters

Process Control Accessories

Process Control Accessories