Gauge Blocks

- Made from artificially aged material

- Outstanding dimensional stability

- Low measurement uncertainty

- 1 Litre

- Granite Cleaner

- Suitable for the Series 517 Black Granite Surface Plates

- Blocks absorb the wear

- Help maintain the condition and accuracy

- Suitable for protecting the measuring surfaces of the working gauge blocks

- A selection of accessories

- Purchase sole items included it the kit

- Easily and quickly build up a custom precision gauge

- Hardened to HV820 (HRC65)

- Excellent rigidity

- 32, 47, 87, or 103 pieces

- Grade 1 or 2

- Alumina-ceramic abrasive stone

- Can be used both for steel gauge blocks and CERA blocks

- Suitable for removing burrs from hard materials

- Wide selection of boxed sets

- Larger sets offer more combination possibilities

- Auxiliary Block Kit

- Efficient reference-setting

- Suitable for Bore Gauge Setting

- 51 or 100 pieces

- Boxed sets complete with a handle

- Pin length 50mm

- Manufacturing tolerance +/- .002mm

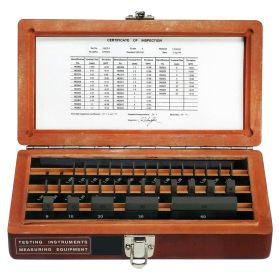

- 8, 47, 88, or 112 pieces

- Grade 0, 1, or 2

- Fitted wooden box

- 10 Pieces

- Inspection Grade: Grade 0

- Optical Flat: 30mm diameter, 12.0mm thick

- Riser Blocks

- Extends the measuring range

- 8, 47, 88, or 112 pieces

- Grade 0, 1, or 2

- Fitted wooden box

- Optical parallel

- Ten gauge block

- Suitable for adjusting and calibrating outside micrometers

- Setting Ring

- Two gauge blocks

- Suitable for adjusting and calibrating calipers

- Excellent rigidity

- 32, 47, 87, or 103 pieces

- Grade 0, 1 or 2

About Gauge Blocks

Gauge blocks are suited to the purpose of setting a variety of measuring instruments. Precise measurements are possible as the tools allow for very accurate calibration of micrometers and other measurement tools. They can be used to very accurately measure objects or distances as well.

Typically constructed from high-grade steel or carbides that resist wear and damage. A gauge block is machined to have two perfectly flat sides within minuscule tolerances that are parallel to each other.

Machinists and others who use precision equipment have found many uses for gauge blocks, such as calibrating equipment and measuring devices. Gauge blocks apply for quality control purposes, such as testing machines and machined parts for precision and adherence to tolerance guidelines.