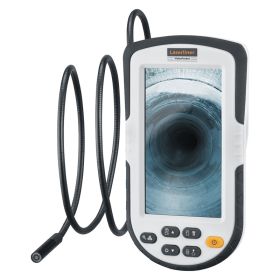

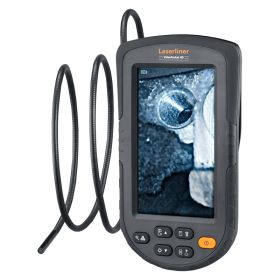

Borescopes & Endoscopes

Borescopes include a camera attached via a flexible cable to a monitor, allowing the user to see what's happening inside machinery, car engines, in walls and other hard-to-reach applications. Available in various sizes.

Find out more about Borescopes & Endoscopes below.

- Portable and lightweight design

- 2.3" TFT LCD colour display

- Battery-operated for cordless use

- HD Streaming

- Digital zoom function

- Onboard Wi-Fi hotspot

- Waterproof IP67

- Six powerful LEDs

- 180° image rotation

- Waterproof, IP67-rated, Ø8mm camera probe with a 640 x 480px resolution

- 77cm (2.5 ft) flexible goose-neck cable which retains its configured shape

- LCD monitor with adjustable brightness and 2x digital zoom

- 5-hour battery operation

- Identify, document, and share

- ExView app compatibility

- Six powerful LEDs

- Easily locate problems

- Large colour display

- 2.5” colour display

- 1.2m ultra-flexible gooseneck

- Ø8.5mm, waterproof camera head with an integrated LED

- 5" TFT LCD colour display

- HD image and video capture

- 4x digital zoom

- Snapshot and Video functions

- LEDs for illuminating dark cavities

- Wireless LAN

- 300mm stainless steel camera probe with a 9mm diameter

- 90° side-view 720p HD camera and two LEDs

- 3”, TFT-LCD monitor with microSD card slot

- Large 3.5" HD colour display

- 32 GB microSD card

- Li-Ion rechargeable battery

- Camera head: 5.2 mm

- Waterproof camera head & cable

- Manual image rotation by 180º

- 6 high-performance LEDs

- True-to-life colours

- Energy-saving automatic shutdown

- Large 5" HD color display

- 8 GB microSD card

- Case with LI-ION Battery

- Long camera unit

- 8 high-performance LEDs

- Evaluation and documentation

- Media gallery

- 10m probe length

- Camera head: 9mm

- Front & side cameras

- 4 high-performance LEDs

- Large 7" HD colour monitor

- Razor-sharp images for precise inspection

- Split screen mode

- Effective problem localisation

- Professional video inspection system

- Sharp digital zoom

- Effective problem localisation

- Professional video inspection system

- Extremely clear digital zoom

- Extended battery life

- Dual-channel camera

- Voice-annotate video recordings

- Lightweight and versatile borescope

- Use interchangeably with 8 Extech IP67, articulating, small-diameter camera probes

- Save voice annotations and photo notes with images and footage

- Probe tip can be controlled via a thumbwheel on the unit

- Excellent quality video on full colour monitor

- Store thousands of images or several hours of video footage on included SD card

- Find objects in difficult locations

- One-handed manual 3D control

- Image rotation in 90° increments

- Lightweight borescope with a five-inch capacitive touchscreen display

- Waterproof, semi-rigid probe with a Ø5mm & 1m length

- Voice Annotations, Photo Notes, Session, & Tag features

About Borescopes

Borescopes (or as they're sometimes known - boroscopes) are visual inspection devices that allow users to see into areas where it might not otherwise be possible. They're ideal tools for a huge amount of applications including aviation turbine and airframe inspections, land-based turbines, power generation, natural gas compressors, large diesel engines, heat exchangers and boilers, down-hole motors/ PC pumps, refineries, chemical processes, nuclear power, wind turbines, paper mills, casting, HVAC and mechanical, military/EOD/law enforcement, mining and exploration and heavy equipment maintenance. In short, they're an extremely practical tool that is perfect for any application where it simply isn't possible for a human to see without potentially costly dismantling of equipment.

A common borescope generally consists of three parts. First, you have the borescope's lens, which is used to see exactly into an application. This is then attached to either a rigid, semi-rigid, or flexible piece of cabling that can be navigated into the target application. Naturally, flexible borescopes are much more adaptable to difficult-to-see applications, as the flexible cabling can be navigated precisely around corners, through holes, and even occasionally submerged into substances. This cabling is then usually attached to a type of viewfinder - depending on the type of device, this may be a simple eyepiece viewfinder, but other devices are video borescopes, and feature large LCD screens for viewing and capturing whatever the viewfinder sees.

When in use, these tools are suitable for many different things. The first and most obvious use of the device is to simply check that things are installed correctly. Once inserted into the application users can begin to use the borescope to check for excessive corrosion, detect loose parts, spot potential leakages, and more. Borescopes are also used quite commonly in the medical industry, but they're generally called by their medical name - endoscopes. These allow doctors to perform intricate surgeries and analyses by passing the scope through the patient's body, meaning there's less damage done overall and internal problems can be spotted and rectified before they become a bigger problem.

Determining that you're using the right type of borescope is an important part of considering which type of device to buy. Flexible versions of these devices, while handy for navigating into tricky areas, often suffer from pixelation and reduced image quality. This is because the flexible cabling used has integrated fibers - which leads to the product being also known as a fiberscope - relying on these fibers to construct an image. Depending on the make and model of the fiberscope the results may be very different - generally, the higher the price, the greater the overall quality of the image obtained. These types of scopes often also contain LED lights on the end, allowing the user to adjust the light as needed to obtain the best image possible (many also offer manual focus options).

In comparison, rigid borescopes may sacrifice the overall ability to enter as many applications as flexible scopes do, but their image quality is generally greater and they generally cost less. This type of scope is best suited for tasks where humans can't see well but easy for a thinner application to enter. This can include looking inside automotive engines and inspecting aircraft turbines, and other applications.

Video borescopes, or inspection cameras, are similar in design to their flexible counterparts. The only major difference between the two types of scope is that the video versions, naturally, can be used to capture video as tests are being performed. This is much more efficient than just using a standard scope, as problems that might be missed in real-time might be spotted at a later date once the video is viewed back. As before, the overall price of the device generally determines the overall video capture quality - cheap borescopes will produce a less crisp image, while more expensive options can be used to capture greater detail and detect more problems. Like flexible scopes, these devices also generally come with integrated light and - depending on the model - can sometimes be submerged into liquids.

It is also worth considering the overall pixel quality of the borescope you're buying. Lower-end devices generally are around 10,000 pixels, but it is recommended that devices with higher resolutions are purchased to maintain image quality (particularly if it is a fiberscope and the image might be more distorted).

Some types of these devices are also USB borescopes, allowing the captured video/images to be uploaded directly to a PC via a USB connection.

Got any questions about the Tester.co.uk range of borescopes? Our team is on hand every weekday to answer any questions about our products, and you can get in touch by phone, email, or by asking a question using the chat feature.