Vibration Testers

Ensure excessive vibration isn't taking place within essential machinery and stop problems before they start with our range of vibration testers and vibration monitoring/testing instruments from Fluke and others.

Find out more about Vibration Testers below.

- Affordable vibration analysis

- Full colour OLED screen

- Stinger-tip accelerometer

- Isolate faults with machinery and equipment

- Shows unbalance, misalignment and looseness

- Also calcuates bearing condition

- Analyse data & trends

- Unlock 9080/9034/9038 Capabilities

- Measure and determine issues with machinery vibration

- Choice of three kits available

- Datalogging - store results and analyse on PC

- Integrates into a system to monitor and report on vibration levels

- Connect up to 4 accelerometers

- Cloud connection for 24/7 monitoring available

- Cost-effective, multifunctional vibration monitor

- 24/7 monitoring

- Set-up alarms using the complimentary Smart Vibration Monitor PC Software

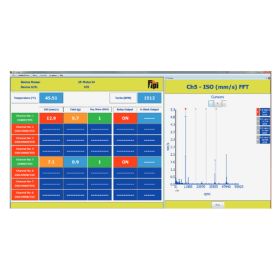

- 800-line spectrum with zoom and cursor

- Built-in colour-coded ISO alarms

- Monitor, analyse, and trend data, and create reports with TPI’s VibTrend PC Software

- 9080 Vibration Meter

- Choice of kit

- 2 Pin Accelerometer & Curly Cable

- Measure, record, and analyse vibration and bearing wear and temperature

- Supplied with C-Trend II Software

- Colour-coded ISO alarms

- 800-line FFT display

- ISO built-in alarms and band filters for unbalance, misalignment, & looseness (3x)

- Intrinsically safe cable-mounted accelerometer with magnet

- Records, analyses, and displays vibration, bearing wear, and temperature

- IECEx/ATEX Zone 0 certified with North American Class 1, Div 1 approval

- Built-in vibration band filters & colour-coded alarms

- Android Tablet

- Protective Case

- Ultra III App

About Vibration Testers

Vibration testing is an important part of evaluating the robustness of common machinery. By simulating the effect of common vibration (sometimes taken to extreme levels) upon a piece of machinery, it is easy to see whether the machine can survive the levels of vibration that will more than likely be regularly applied to it.

Many common machines vibrate by their very nature. Car engines, washing machines, and common industrial machinery all vibrate to some extent, which can lead to errors and faulty parts if the machine isn't robust enough to withstand the effects of vibration. That's why it's extremely important to perform vibration testing on products before shipping them out for commercial use, as performing the test simulates the effects of constant vibration over time, allowing necessary repairs to be made when they're needed; that is, before shipping out for commercial purchase.

Vibration testing can also be used in smaller doses to complete diagnostic reports on machinery, allowing you to see which internal component is the cause of an error.