Voltage, Current & Loop Calibrators

Specific instruments for calibrating voltage, current and loop. Many of the instruments in this section are multifunctional, and can calibrate more than one parameter. Includes portable calibrators and bench-top calibrators ideal for laboratories.

Find out more about Voltage, Current & Loop Calibrators below.

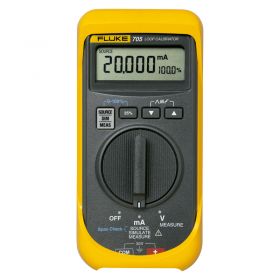

- Long battery life (40 hours)

- 0.01 mA resolution

- backlit dual display

- Source, simulate and measure mA

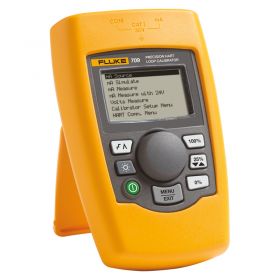

- Highly accurate (0.02%) with resolution down to 0.001mA

- Simultaneous mA and % of span display

- Simultaneous mA and % span measurements

- Quick and easy to use

- For calibration, repair and maintenance of current loops

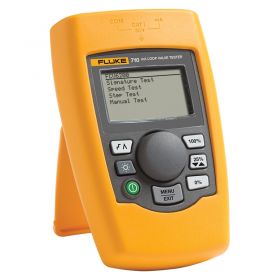

- Wide range of ampage

- 0.2% accuracy

- Option for linear ramp of 25% steps

- Portable handheld unit

- Measure and source voltage or current

- Power loops

- Two in one digital multimeter and mA loop calibrator

- Compact design

- Multitude of measurement functions and ability to measure, source and simulate up to 20mA DC

- Measures mA signals without breaking the loop

- Best in class with 0.2% accuracy

- Dual backlit display with mA measurement and percent of 4 - 20 mA span

- Loop calibrator and DMM in one tool

- Built-in HART resistor

- Full suite of multimeter functions including voltage, current and continuity

- Calibrate volt and mA sources with the greatest of ease

- Works with Fluke 80 series digital multimeters

- Robust, lightweight and easy-to-use

- HART communication tool

- Small, portable and rugged device

- Versatile range of advanced features

- Digital multimeter and mA loop calibrator

- Facilitates a connection between the Fluke 789 and Fluke Connect App

- Current clamp capable of wirelessly transferring measurements

- Optimised for testing complex smart valves

- Integrated signature, step, speed and bump testing procedures

- Includes a HART modem for communicating HART commands

About Voltage, Current & Loop Calibrators

Also known as current loops, 4-20mA sources are one of the most common methods used in the process industry for transmitting data between sensors and the applications that control and monitor them. The main advantage of a current loop is it can be combined with a huge variety of different sensors to measure temperature, pressure, liquid flow, or light. This data is then compatible with a wide range of different management applications that interoperate with the data and react accordingly.

4-20mA current loops work by taking the results from the sensor and converting it to a proportional current. This means that a zero result causes a 4mA to be transmitted and a 20mA current is sent when the sensor is at full capacity. This information is then sent through copper cables to a receiver at the controller. The controller then decodes the sent signal into the format that is required by the process monitoring application.

The drawback with this method is that over long distances the signal can eventually erode as the voltage begins to wane. An engineer must also be careful when laying these cables to ensure that no electrically noisy systems are located close by, otherwise, they can affect the signal. The main precaution that can be taken is to ensure the use of shielded cabling but this can become too expensive if used over long distances.

To ensure that a current loop is operating effectively engineers often use current calibrators to test the cables and ensure that there are no issues that need resolving no matter what their source.