Insulation & Continuity Testers

Range of insulation and continuity testing instruments including Megger insulation testers, insulation resistance testers, Fluke testers and insulation meters from Amprobe, DiLog, Seaward, Metrel, Martindale, Kewtech, Extech and more.

Find out more about Insulation & Continuity Testers below.

- 1-second test cycle

- 24V DC test voltage

- PASS/ FAIL indication

- Easy and quick local/remote continuity verification

- Lightweight for hands-free attachment to wires

- Bright flashing LED indicators and remote test probe

- Built in continuity buzzer

- Tough outside casing

- Tests for voltage and current

- Audible and visual indicators

- Safety measure included

- Test leads and battery included in kit

- Continuity tester with a buzzer and optical display

- Voltage proof up to 600V

- Test resistance, semi-conductors, polarity, light-bulbs, and fuses

- Simple dial and push-button interface

- Large LCD screen

- Four jacks for testing

- Compact and lightweight with included protective cover

- Insulation resistance measurements up to 5.5GΩ

- Also tests polarisation index and dielectric absorption ratio

- Measure insulation resistance to 20.0GΩ

- Selectable test voltages to 1000V

- AC/DC voltage measurements to 600V

- Conducts insulation tests and voltage detection

- Hands free operation possible with lock power on

- Super large backlit dual display

- Tests for both insulation and voltage

- New Lock Power On function

- Also detects and measures continuity, resistance and AC voltage

- 0.01 MΩ - 10.00 GΩ resistance range

- Data storage

- Automatic power off

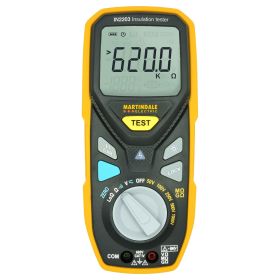

- Combined insulaition tester and digital multimeter

- Insulation resistance to 20GΩ

- AC/DC voltage, resistance and continuity functions

- High spec insulation resistance tester

- Autoranging

- Bright backlit screen

- A hand held tester designed to perform insulation and continuity tests

- Four test voltage ranges: 125, 200, 500, 1000V

- Measurement ranges from 0.01Ω to 4GΩ

- Conduct insulation tests at 1000V, 500V and 250V

- Buzzer function for ‘belling out’

- Hands-Free function

- Five insulation test voltages

- Voltage, resistance & continuity measurement

- 200mA Earth bond test

- PI & DAR measurement

- Lightweight

- Test up to 500V

- Easy-to-use interface

- Comparison function

- Timer measurement

- Automatic discharge

- High voltage output alarm

- 250V, 500V and 1000V testing capability

- Audible buzzer notifications

- Insulation testing up to 100mOhm

- Measure insulation resistance up to 1000 MΩ using 250V, 500V and 1000 V test voltages

- Measure continuity between 0.01Ω and 100Ω

- Integrated voltmeter and automatic test halting when a voltage of 50V or above is detected

- Ergonomic, easy-to-use, accurate, 18th Edition single-function tester

- Run insulation tests at 50V, 100V, 250V, 500V and 1000V

- Determine breakdown voltage and conduct continuity tests with an audible alert

- Insulation resistance measurements up to 20MΩ

- Voltage and earth resistance measurements

- 500V and 1000V test voltages

- Small and portable for testing on the go

- Selectable measurements using easy-to-use dial

- Locking capability when not in use

- Specifically designed by electricians to deliver optimum performance

- Automatic power down functionality to preserve battery life

- Durable and robust design

About Insulation & Continuity Testers

Insulation is a vital part of any electrical system. Correctly installed insulation ensures that the current flowing through a system remains on the designated path it should be moving through and breakdowns in the overall insulation of a system can cause leakage current to flow, leading to problems and potential hazards.

The overall insulation of any system is susceptible to degradation over some time. As standard, the insulation of an electrical system or appliance should be solid enough to constrain as much leakage current as possible until the overall level is completely negligible, but many outside factors can affect the overall insulation over some time, thus increasing the risk of higher levels of leakage current.

Parameters that can affect the overall amount of insulation present in a system vary greatly; everything from cuts in wiring, vibrations, pollution (corrosive materials), and even dust and dirt in the air can gradually erode at insulative properties, effectively rendering them less useful over time.

Insulation test equipment is designed to effectively measure the level of insulation left on an electrical system. Knowing the overall level of insulation allows the tester to determine whether the insulation is still safe for use, or whether steps have to be taken immediately to make sure that the insulation is repaired to an acceptable level.

Common insulation testers are generally used to perform two different forms of electrical measurements. These measurements are obtained by testing between the conductors that carry current when energized and other parts of the system in which no current should ever flow under normal operating conditions. To gain an overall reading of the level of insulation resistance present two things must be measured: the actual leakage current flowing through the installation, and to measure the actual resistance of the insulation.

Insulation is also commonly measured to verify quality control of manufactured electrical devices, ensure electrical devices meet codes and standards (safety compliance), determine a device's performance over time (preventive maintenance), and determine causes of failure in troubleshooting scenarios. You can further classify insulation resistance testing into different testing types. These are:

- Design testing

- Production testing

- Acceptance testing

- Verification testing

- Preventive maintenance testing

- Fault locating testing

The actual type of insulation resistance tester needed to be used also varies on an application-by-application basis. Although standard ohmmeters commonly found on devices such as multimeters can be used to measure insulation, these generally do not have the measurement range required to determine insulation effectively.

Two main instruments are used to measure insulation resistance - the first is the megohmmeter, a tester that's the same as a standard ohmmeter but has a higher measurement range to accommodate the needs of insulation. The second tester is known as a hipot tester, and these instruments measure insulation resistance by measuring leakage current. Hipot testers apply a high test voltage between two different conductors or between a conductor and ground and measure the leakage current. An excessive amount of leakage current (in apms) indicates a lower resistance or breakdown in insulation. Hipot tests almost always involve applying a test voltage that is several times higher than the specified operating voltage of the cable or device being tested.

Continuity Testing

Continuity testers are used to test for a complete flow path (open, broken, or closed) in any de-energized low-resistance application. They tie in with insulation testers, as broken continuity of a flow path generally means that current is being lost somewhere, which may be the result of a break in insulation levels.

This type of tester is often integrated into an insulation testing device, allowing users to carry out both testing types without the need to switch instruments. If you do prefer to operate with separate instruments both insulation and continuity testing devices are available as separate products as well.

Continuity testers can also contain integrated voltage measurement capability using two-pole probes.