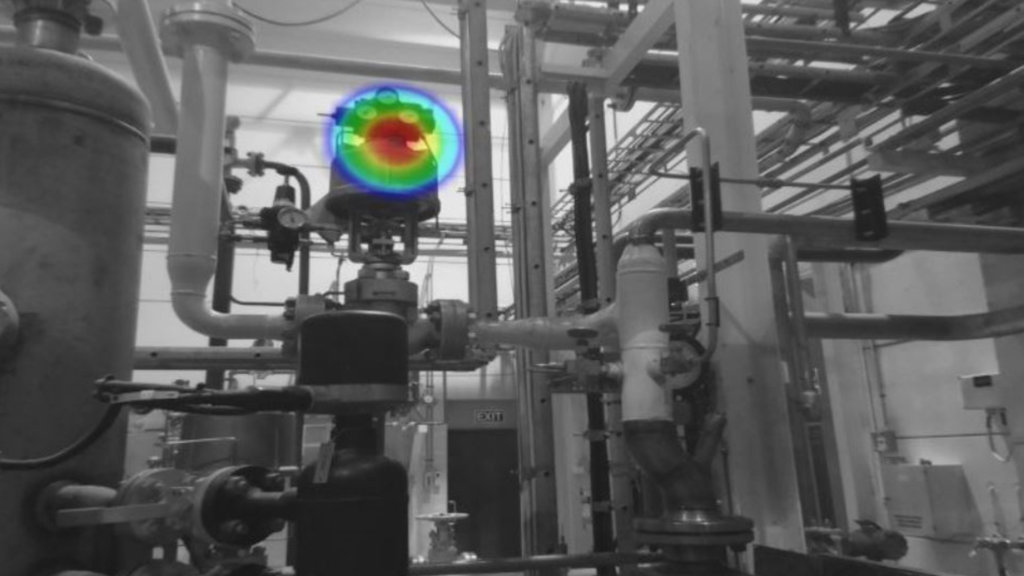

Acoustic imaging cameras, otherwise known as sonic or ultrasonic imagers, are popular amongst facilities managers, especially those working in industrial or high-voltage settings. They are extremely easy to use and highly effective at finding air/pressurised leaks and partial discharge/corona. Acoustic cameras detect audible and/or ultrasonic sound; convert it into a sound map; then superimpose this map onto a digital image of the inspection area, allowing you to pinpoint the source of the leak or electrical fault accurately, simply, and quickly. As sonic imaging is a relatively new preventative maintenance/inspection technology, it can be difficult to know what makes a good acoustic camera. Thankfully, Teledyne FLIR has outlined six things to look for when purchasing an ultrasonic imager.

Quick Links

- 1.) Effective Frequency Range

- 2.) Optimal Number of Microphones

- 3.) Sound Detection Range

- 4.) Microphone Placement

- 5.) Microphone Performance

- 6.) Intelligent Analytics

- Teledyne FLIR Si124 Industrial Acoustic Imaging Camera

- Further Information

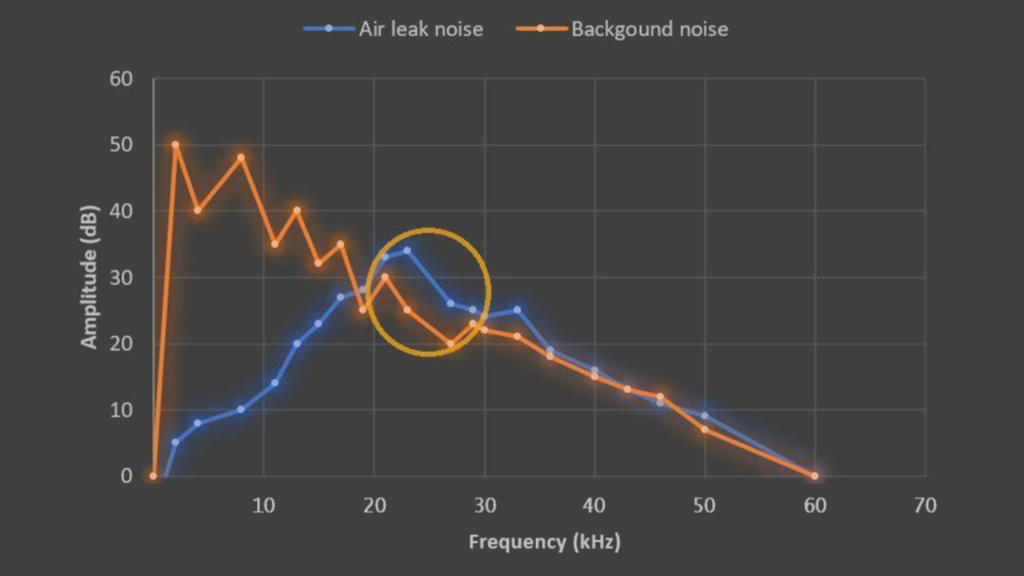

1.) Effective Frequency Range

Acoustic cameras with wide frequency ranges are not necessarily better as it does not follow that they will be able to pick up more sounds. Therefore, knowing what you need your sonic imager to locate is key to identifying models with suitable frequency ranges:

- Finding compressed air leaks in noisy factories: 20-30 KHz

- Safely detecting partial discharge: 10-30 KHz

2.) Optimal Number of Microphones

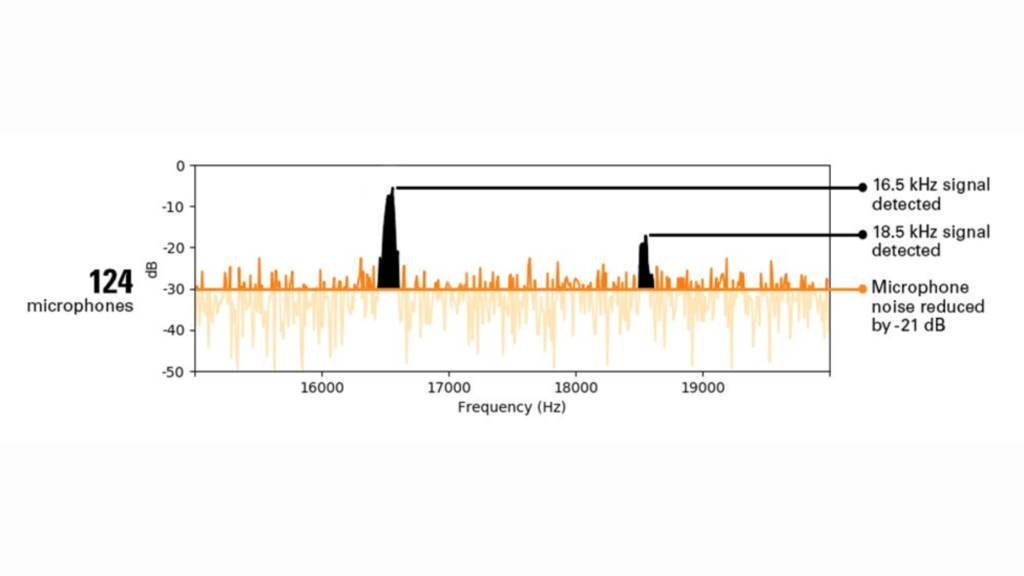

As ultrasonic imagers are generally used to detect quiet noises, then the more microphones the better! (To a degree, see point 5 for more details.) In addition to capturing sounds, microphones produce a small amount of noise. The more microphones you have the better the sound-to-noise ratio, allowing you to pick up more sound without noise interference.

3.) Sound Detection Range

Increasing the number of microphones also improves your chances of capturing quiet sounds from a greater distance. Teledyne FLIR explains that, for example, by quadrupling the number of microphones you can double the sound detection range.

4.) Microphone Placement

Having a multitude of microphones is no good if they are spread out all over the camera. Microphones have to be grouped closely together in order to collect enough data to ascertain the location and direction of sounds.

5.) Microphone Performance

Despite espousing the advantages of having more microphones (see points 2 and 3), there comes a stage when the number of microphones begins to hamper the performance of the sonic imager. This is because the camera either needs a lot of processing power or its resolution must be diminished to accommodate the masses of microphones.

Teledyne FIR takes optimising microphone performance very seriously. It is at the forefront of the Si124 Ultrasonic Imager’s design. Equipped with 124 microphones and advanced processing power, Teledyne FLIR’s Si124 Acoustic Camera delivers industry-leading detection sensitivity, sharp acoustic image resolution, and excellent range.

6.) Intelligent Analytics

Finally, make sure you consider the acoustic imager’s computing power and analytics. Look for models that offer on-camera analytics; automatic image upload when connected to Wi-Fi; easy-to-understand reporting; and predictive analysis using an AI/web tool. Teledyne FLIR understands the value of intelligent analytics and makes a point of incorporating all the aforementioned capabilities into the Si124 Acoustic Camera.

Teledyne FLIR Si124 Industrial Acoustic Imaging Camera

Cordless, lightweight, and easy to use, there are two versions of the Teledyne FLIR Si124 Acoustic Camera available: one for leak detection and one for partial discharge detection.

Teledyne FLIR Si124-LD Industrial Acoustic Camera - Leak Detection

Price: £11 339 (Ex VAT)

- Locate pressurised leaks in compressed air systems

- One-handed operation

- High-resolution digital camera

- 124 microphones

- Images are automatically saved to the Cloud

- View the leak rate

- Quantify leaks

- Calculate energy loss

- Battery operated

Teledyne FLIR Si124-PD Industrial Acoustic Camera - Partial Detection

Price: £13 649 (Ex VAT)

- Detect partial discharge in high-voltage electrical systems

- One-handed operation

- High-resolution digital camera

- 124 microphones

- Images are automatically saved to the Cloud

- Detect PD up to 130m away

- Severity Assessment tools - ascertain the level of danger; determine the type of PD; classify PD

- Battery operated

Further Information

Download Teledyne FLIR’s 6 Things to Look for in an Acoustic Imaging Camera here.

6 Things to Look for in an Acoustic Imaging Camera

You can view Teledyne FLIR's Si124 Industrial Acoustic Imaging Cameras below.

Buy the Teledyne FLIR Si124-PD Industrial Acoustic Imaging Camera – Partial Discharge Detection

Buy the Teledyne FLIR Si124-LD Industrial Acoustic Imaging Camera – Leak Detection

For further help or advice regarding acoustic imaging cameras, please contact our Sales team on 01642 931 329 or via our online form.