“As may be necessary to prevent danger, all systems shall be maintained so as to prevent, so far as is reasonably practicable, such danger.”

This rule, which is enforced under Regulation 4(2) of the Electricity at Work Regulations formed in 1989, states that electrical equipment used within working environments must be maintained to a safe level for use safely by any individual who happens to use them.

Although this is pretty obvious, there’s a severe lack of understanding among several work industries about exactly how these rules are enforced – after all, how far does ‘maintaining’ systems go? Does it require extensive testing by qualified electricians, or is it simply as easy as taking a look to see if there’s any obvious damage to an appliance?

The answer is one that has multiple levels. From a non-electrician standpoint, it’s really extremely hard to nail down exactly what is legally required to be tested under the current regulations, particularly because there are different rules that apply to different aspects of electrical testing.

One of the most common safety checks within the workplace is PAT (portable appliance testing) and the next section hopes to give some clarification on how this complex requirement works.

PAT-Testing: The Myths and Legal Requirements

If you work in any form of business, you’ve likely heard of PAT-testing. Indeed, for many organisations PAT testing is an extremely long, expensive process that requires the testing of every electrical appliance your work force and any other members of the public might interact with.

It may be that your business has been contacted regularly by firms selling PAT-testing services, claiming that your appliances should be checked annually. First things first – this is a myth. PAT Testing is not a legal requirement, but to stay in line with regulations such as The Health and Safety At Work Act (1974), The Management Of Health and Safety At Work Regulations (1999) and The Electricity At Work Regulations (1989) it is recommended that PAT testing is carried out regularly.

- The Health and Safety at Work Act (1974) briefly states -

Every Employer holds a Duty of care to ensure the safety of all persons using their premises.

- The Management of Health and Safety at Work Regulations (1999) briefly states -

Every employer shall make suitable and sufficient assessment of:

The risks to the health and safety of his employees to which they are exposed while they are at work, and

The risks to the health and safety of persons not in his employment arising out of or in connection with the conduct by him of his undertaking.

- The Provision and Use of Work Equipment Regulations (1998) briefly states –

Every employer shall ensure that work equipment is suitable for the purpose for

which it is used or provided

- The Electricity at Work Regulations (1989) briefly states –

All Electrical Systems and Equipment shall be maintained so as to prevent, so far as is reasonably practicable, any danger

Testing is to be carried out by competent personnel

Test results must be retained so as to maintain traceability

In short, under the guidelines of the various regulations it is generally the legal responsibility of the company to ensure that all electrical appliances are in safe working order. However, it is not a legal requirement, nor does PAT testing have to be performed every single year like some firms would have you believe.

There are a lot of different rules relating to actually performing PAT testing itself, and the time scale between tests varies greatly depending on the environment the appliances are placed in, and the general condition of the equipment. In many offices, for example, it is perfectly acceptable to perform what is known as a visual check on equipment, which can easily flag up whether something is wrong or not. Frayed cables, exposed wiring etc are all common problems, and are a quick, inexpensive indication that something isn’t in correct working order.

In comparison, appliances used in dangerous environments, or areas used more commonly by the public where electricity is a danger (such as swimming pools/leisure centres) are required to perform PAT testing more frequently to ensure that all the equipment used is constantly in safe working order, as it is used by people who are using the facility but are not actually under contracted employment.

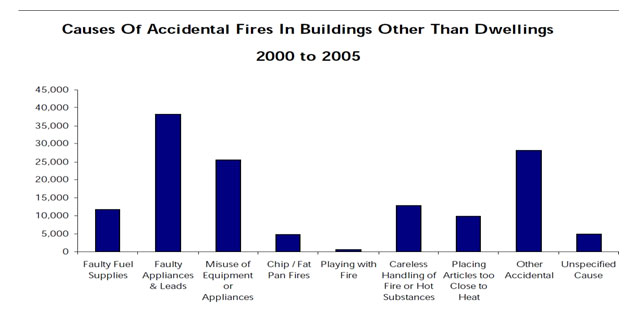

According to figures gained by the Department for Communities and Local Government, in 2005 the causes of accidental fires in buildings are the majority of the time caused by faulty equipment.

According to this chart, over 50,000 accidents over the course of five years outside domestic properties were caused by faulty appliances, leads, or the misuse of equipment or appliances.

It is statistics like this that show you exactly how important PAT testing is. While it’s not necessarily a legal procedure, leaving your appliances to become dangerous ultimately could end up in work related accidents, damage to employees/equipment, accident claims and all kinds of other legal red tape you could easily avoid by carrying out regular PAT testing.

Fixed Wire Installations: The Hidden Dangers

Fixed wiring refers to all the wiring that is fixed into place, be it behind walls, hidden in transformers or under the floor or in the ceiling. Generally this kind of wiring is used to power something that will constantly remain fixed in place, and can refer to the wires of large machinery, or – more commonly – refers to the wiring placed behind distribution boards, main sockets and switches.

For more information on fixed wiring, you can visit our earlier post where we ask just how often the testing procedure should be performed.

Written by Barry Atkins at www.tester.co.uk