Teledyne FLIR’s new One Edge and One Edge Pro Wireless Thermal Cameras are designed for use with both Android and iOS smartphones. In previous blogs we have illustrated how these simple-to-use yet sophisticated thermal imagers have helped property owners find and address sources of heat loss, resulting in significant savings on energy bills, as well as decreased emissions. We have also noted the ways they may provide cost-saving and animal welfare solutions within the agricultural sector, for example, by spotting cattle lameness early or ensuring proper insulation of poultry barns. In addition to this, we have published case studies on using thermal imagers, such as the Teledyne FLIR One Edge/Pro, to defend against unplanned downtime. In this blog, we will be highlighting how the Teledyne FLIR One Edge/Pro Thermal Cameras can improve the efficacy of automotive diagnostics, saving mechanics valuable time.

Quick Links

- How Can Thermal Imaging Help Vehicle Mechanics?

- Introducing the Teledyne FLIR One Edge Thermal Cameras

- Five Faults You Can Find Using the Teledyne FLIR One Edge Thermal Cameras

- Further Information

How Can Thermal Imaging Help Vehicle Mechanics?

Heat presence or absence often indicates an impending failure. Therefore, thermal imaging, a technology that maps heat intensity and distribution, is perfect for pinpointing problems quickly and precisely. For example, resistance in mechanical and electrical components will generate heat that is easily spotted on a thermal image. Consequently, you can identify exactly which component is faulty exceedingly quickly. Traditional diagnostic methods such as vibration and noise testing, fault detection using a multimeter, or running diagnostic software, all take longer to implement and may not be able to identify with any certainty which component is failing.[1]

Identify Mechanical Issues

All mechanical components create heat due to friction. However, failing parts will often generate greater temperatures due to increased friction. A thermal camera allows you to see this immediately. Thermal imaging is ideal for identifying common mechanical problems such as broken seals, seized-up parts, or failing components such as brake callipers.

Worn seals in brake callipers can prevent the pistons from turning properly which, in turn, causes rotor warping, vibration, and uneven wear and performance. Rather than inspecting the brake callipers visually, which can be time-consuming, thermal cameras allow mechanics to see instantly if one calliper is generating more heat than the other and is, therefore, likely to be stuck.[2]

Diagnose Electrical Defects

Electrical defects, such as loose connections, faulty components, or high resistance, generate heat within electrical systems. Thermal cameras offer a simple, swift method of identifying these hotspots. Additionally, cold spots or cooler areas may also suggest a problem. Often, they indicate that a component needs to be replaced or that power is not being delivered properly.

Thermal imaging has proven effective within an array of other industries, from electrical to construction to agriculture; it can be just as revolutionary within the automotive sector. For example, thermal cameras make diagnosing issues with heating elements easy. Any area of the element that is not operating correctly will appear colder on the thermal image.

Moreover, the efficacy of heating and AC systems can be assessed quickly as a thermal scan will reveal straightaway if the vehicle is reaching the intended temperature. Similarly, high-resistance connections generating hotspots can be promptly found using a thermal camera. This is particularly useful when monitoring the condition of batteries and other high-voltage components in hybrid and electric cars.[3]

Introducing the Teledyne FLIR One Edge Thermal Cameras

New additions to Teledyne FLIR's range, the One Edge and One Edge Pro Thermal cameras are infrared imaging modules that connect wirelessly to your iOS or Android smartphone or tablet. As such, they transform your smart device into a thermal imager. Equipped with an array of features characteristic of Teledyne FLIR thermal cameras, the Teledyne FLIR One Edge and Edge Pro are ideal for identifying moisture intrusion; finding insulation deficiencies; HVAC/R inspections; and pinpointing electrical and mechanical faults, including those common to vehicles.

Teledyne FLIR One Edge Thermal Camera

Price: £299 (ex VAT)

- IR Res: 80 x 60px

- Thermal Sensitivity: 70mK

- Temp Range: -20°C to +120°C

- Accuracy: ±3°C/5%

- MSX imaging

- Supports use with iOS & Android

- Clips onto your smartphone

- Battery life: 2.5 hours

Teledyne FLIR One Edge Pro Thermal Camera

Price: £479 (ex VAT)

- IR Res: 160 x 120px

- Thermal Sensitivity: 70mK

- Temp Range: -20°C to +400°C

- Accuracy: ±3°C/5%

- MSX imaging

- Supports use with iOS & Android

- Clips onto your smartphone

- Battery life: 2.5 hours

Five Faults You Can Find Using the Teledyne FLIR One Edge Thermal Cameras

The Teledyne FLIR One Edge/Pro Thermal Cameras' compact design coupled with their wireless streaming and MSX imaging capabilities, make them particularly adept at locating and diagnosing faults in automobiles.

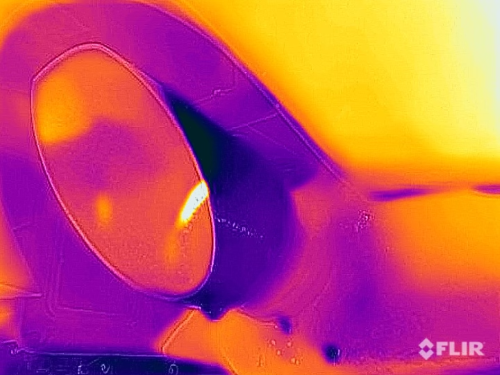

1.) Exhaust Leaks

Simply and swiftly scan the manifold, pipes, visible joints, and gaskets using the Teledyne FLIR One Edge/Pro Thermal Camera to discover temperature variations that may indicate a leak. MSX imaging mode overlays digital details onto the thermal image, increasing clarity and making it easier for you to locate the source of leaks and/or any other anomalies present within the exhaust system.[4]

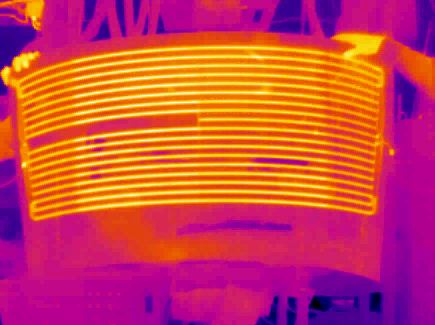

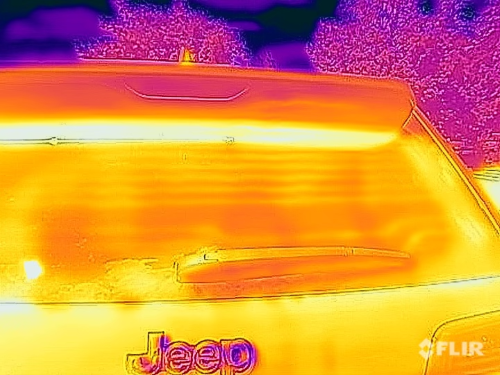

2.) Malfunctioning Heating Elements

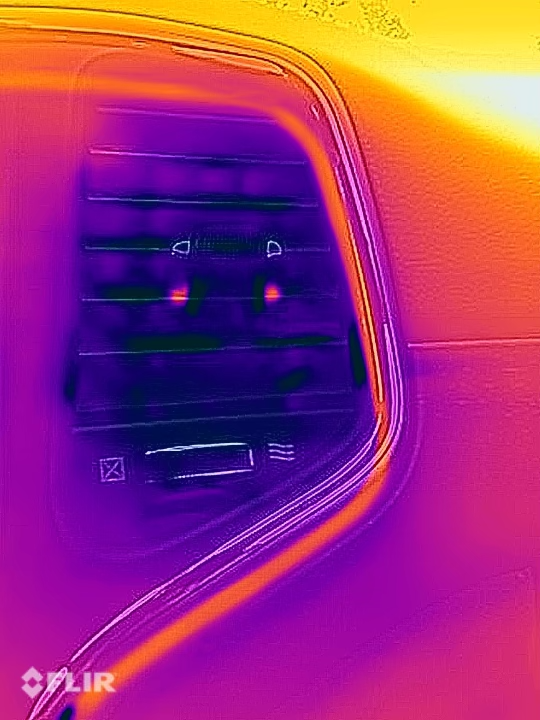

In the winter, it is crucial that defrost grids operate optimally. The Teledyne FLIR One Edge/Pro Thermal Camera allows mechanics to assess the functionality of heating elements at once. This is because the heat distribution is mapped across the thermal image, letting professionals pinpoint defective sections or elements. Additionally, wireless streaming enables collaborative analysis as technicians can compare temperatures inside and outside the vehicle. As a result, it is easier and quicker to diagnose and repair malfunctioning heating elements.[5]

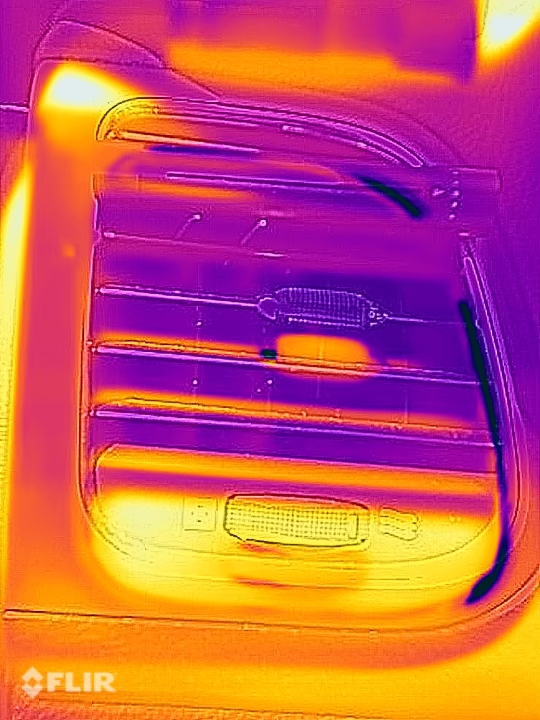

3.) Air Conditioning Issues

Identifying air conditioning issues is notoriously challenging as, within vehicles, the majority of these systems are often hidden or awkward to access. Yet, utilising the wireless streaming capabilities of the Teledyne FLIR One Edge/ Pro Thermal Module, the camera can be positioned in such a way as to view enclosed components while the engineer conveniently analyses thermal footage on their smartphone or tablet. What's more, wireless streaming means multiple engineers can view different parts of the concealed system, as well as the visible vents, simultaneously, making identifying overheating components, blockages, or refrigerant leaks effortless.[6]

4.) Faulty Brake Drums

As with air conditioning systems, traditionally it has been difficult to inspect brake drums due to limited access and visibility. Nevertheless, the Teledyne FLIR One Edge/ Pro Thermal Camera’s wireless streaming significantly improves the ease and efficiency of these inspections. This is because mechanics can move freely around the vehicle, holding the thermal imaging module in positions that provide observation of the brake drums, while viewing the thermal footage comfortably via their smartphone or tablet. Consequently, automotive professionals can spot anomalies, such as uneven heating, overheating, or signs of wear easier, earlier, and faster.[7]

5.) Catalytic Converter Problems

Similarly, the location of catalytic converters makes them hard to inspect. Once again, the Teledyne FLIR One Edge/Pro Thermal Camera's wireless streaming capabilities offer an effortless solution. Mechanics can move around the vehicle, unrestricted by cables or connections, to capture multiple images of the catalytic converter from an array of angles. Furthermore, the compact size of the Teledyne FLIR One Edge/ Pro Thermal Imager, means it can access tighter, hard-to-reach spaces.[8]

Further Information

To find out more about how Teledyne FLIR’s One Edge and One Edge Pro Thermal Cameras can be used to improve automotive diagnostics, and for further advice regarding our range of Teledyne FLIR thermal cameras, please contact our Sales team on 01642 931 329 or via our online form.

Alternatively, you can view our eclectic range of Teledyne FLIR Thermal Cameras here, including the One Edge and One Edge Pro models.

Browse Teledyne FLIR Thermal Cameras

View the Teledyne FLIR One Edge Thermal Camera

See the Teledyne FLIR One Edge Pro Thermal Camera

As mentioned, the Teledyne FLIR One Edge and One Edge Pro Thermal Cameras are suitable for an array of applications across multiple sectors. To demonstrate this, we've published a variety of blogs detailing these applications.

PASS Provides Teledyne FLIR Thermal Cameras for Octopus Energy Home Efficiency Surveys

Teledyne FLIR Thermal Cameras Used to Tackle Cost of Living Crisis

Defending Data Centres Using Teledyne FLIR Thermal Cameras

Catch Cattle Lameness with Economical Thermal Cameras

PASS Provides FLIR Thermal Camera for Barn Ventilation Report

[1] Teledyne FLIR, Achieve More Efficient Auto Inspections with Thermal Imaging, last accessed 13 December 2023.

[2] Teledyne FLIR, Achieve More Efficient Auto Inspections with Thermal Imaging.

[3] Teledyne FLIR, Achieve More Efficient Auto Inspections with Thermal Imaging.

[4] Teledyne FLIR, Five ways the FLIR One Edge Pro can be used to streamline automotive inspections, last accessed 13 December 2023.

[5] Teledyne FLIR, Five ways the FLIR One Edge Pro can be used to streamline automotive inspections.

[6] Teledyne FLIR, Five ways the FLIR One Edge Pro can be used to streamline automotive inspections.

[7] Teledyne FLIR, Five ways the FLIR One Edge Pro can be used to streamline automotive inspections.

[8] Teledyne FLIR, Five ways the FLIR One Edge Pro can be used to streamline automotive inspections.