Prioritising sustainability and energy efficiency is not only good for the environment but also good for business. Energy inefficiency significantly increases overhead costs and, therefore, depletes profits. Moreover, it is becoming increasingly common for tenders to request evidence of environmental policies and their effectiveness. A failure to provide these could result in losing lucrative contracts. However, first companies must ascertain how they are losing energy and where they can make potential improvements. Fluke’s six essential tools allow facilities managers to do just that, as well as monitor alterations to assess their efficacy.

Quick Links

- Why is Energy Management Important?

- Where Can Businesses Make Energy Savings?

- What Are Fluke’s Six Essential Tools for Energy Management?

- Further Information

Why is Energy Management Important?

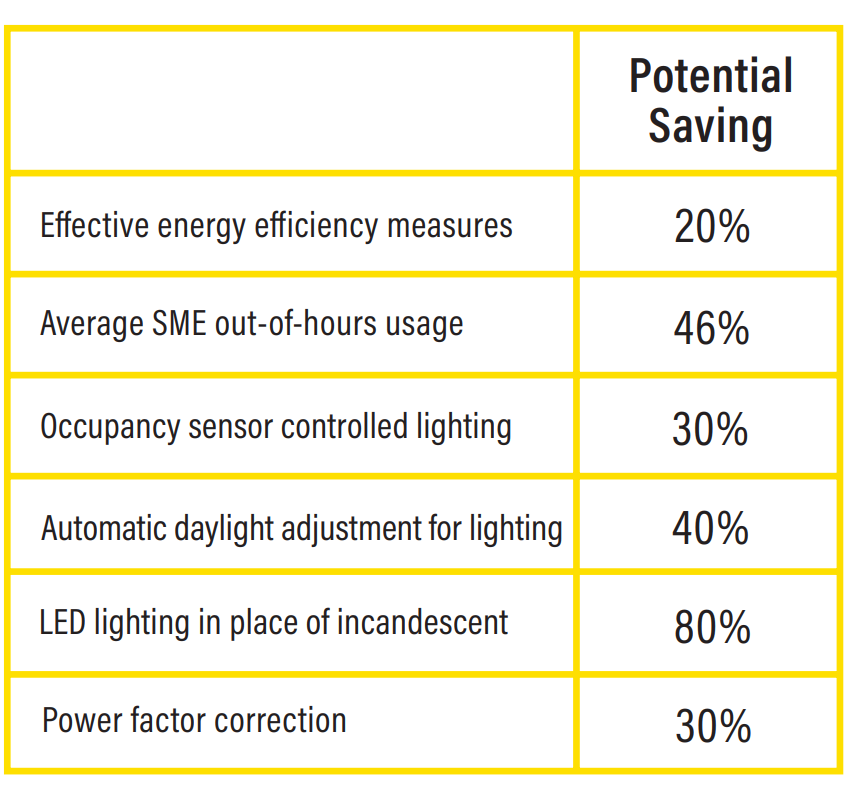

Recent hikes in energy prices and increased pressure to meet environmental targets have refocused many businesses’ attention onto the quality and quantity of their energy use. Surveys found that ensuring energy efficiency results in significant savings. For example, the Carbon Trust estimates that by improving efficiency and deploying energy conservation tactics, businesses can reduce their energy bills by up to 20%. [1]

Meanwhile, a British Gas survey of 6000 SMEs (small and medium-sized enterprises) uncovered that 46% of their electricity usage occurred outside of working hours. The study estimated that leaving office equipment switched on over the weekend and during bank holidays could cost the average SME up to £6000. It also predicted that switching off non-essential office equipment at the end of the day may result in energy savings of 12%.[2]

Data acquired by the Carbon Trust and British Gas pertaining to the potential cost savings of a variety of energy efficiency measures is outlined in the following table.

Elsewhere, assessments made by US Department of Energy found that the average poorly maintained US plant loses 20% of its compressed air capacity through leaks; other experts estimate this to be higher, for instance, New Zealand’s government places the loss at between 30 and 50%. The US Department of Energy explains that a single 3mm leak (1/8”) in a compressed air line can cost companies upwards of $2500 per year (approximately £1991[3]). [4]

As illustrated managing energy usage and efficiency can be lucrative, especially as many tenders require evidence of successful environmental policies. Furthermore, for many businesses not maintaining good energy efficiency could have negative effects. For instance, Streamlined Energy and Carbon Reporting (SECR) regulations require qualifying UK businesses (approximately 11 900 companies as of 2019) to disclose their energy use and carbon emissions alongside reference metrics.[5] As such, maximising energy efficiency while minimising carbon emissions is not only advantageous for the environment but also serves to improve businesses’ profitability and reputation.

Where Can Businesses Make Energy Savings?

An investigation found that 39% of carbon emissions are emitted by buildings. 28% of these emissions are attributed to operational activities as well as cooling, heating, and powering properties. Therefore, these are the areas facilities managers may wish to investigate and address. However, a survey by the IWFM (Institute of Workplace and Facilities Management) found that, while 70% of professionals asked said reducing the energy usage and carbon emissions of buildings was a key priority, a staggering 62% of these respondents felt they did not have access to the data required to meet sustainability targets.[6] It is this uncertainty that Fluke’s paper seeks to address. Within their document, titled The Best Tools for Energy Management and Sustainable Maintenance, Fluke highlights the following parameters as essential to maintaining sustainability and ensuring energy efficiency:

- Air Quality

- Air ventilation

- Power quality

- Energy consumption

- Energy waste (including heat loss)

- Air leaks in compressed air/gas systems

The report also details the best Fluke tools for monitoring each of these parameters.

Download Fluke’s Paper on The Best Tools for Energy Management & Sustainable Maintenance

What Are Fluke’s Six Essential Tools for Energy Management?

Below are examples of Fluke’s essential tools for energy management as detailed in the paper, The Best Tools for Energy Management and Sustainable Maintenance.

Air Quality

Fluke recommends using a temperature and humidity meter to assess air quality. This information can be used to verify the functionality of air conditioners and inform decisions about their energy consumption.

Recommended Product: Fluke 971 Temperature Humidity Meter

- Measures temperature and humidity simultaneously

- Temperature range: -20 to 60°

- Humidity range: 5 to 95% RH

- Backlit dual display

- Integrated sensor evaluates ambient air conditions

- Measure dewpoint and wet bulb

- Internal memory: stores up to 99 readings

- MIN/MAX/AVG functions

- Data hold function

- Ergonomic design

- Built-in belt clip

- Low battery indicator

Air Ventilation

Similarly, Fluke advocates using an airflow meter to determine the effectiveness of ventilation systems. This is achieved by measuring the air’s flow, temperature, velocity, pressure, and differential pressure.

Recommended Product: Fluke 992 Airflow Meter

- Measure air pressure, air velocity, air flow, and temperature

- IP40

- Battey life: up to 375 hours

- Data storage: up to 99 readings

- MIN/MAX/AVG functions

- Data Hold function

- Coloured hoses

- Rugged design

Power Quality

The energy efficiency of electrical installations is impacted significantly by the circuit’s power quality. Unbalance, total harmonic distortion (THD), overvoltages, voltage regulation (dips and swells), and power factor can all be affected by changes, additions, or adjustments to the system. Consequently, Fluke advises monitoring power quality to reduce energy waste.

Recommended Product: Fluke 1775/1777 Power Quality Analysers

Fluke 1775 Power Quality Analyser

- Two-in-one PQA and PQ meter

- Easy-to-use, streamlined interface

- Automatic measurement capture

- Captures over 500 power quality parameters

- Measures harmonics, dips, swells, unbalance, voltage, current, and power

- High-speed transient capture up to ±8kV

- Transient capture sample rate: 1MS/s

- PQ meter function

- Large, bright touchscreen display

- Navigation buttons

- Guided setups

- Create custom views

- USB interface

- Wi-Fi interface

- Transfer data without interrupting monitoring

- Compatible with Fluke Energy Analyse Plus Software

- One-click reporting function

- Can be powered directly from the measured circuit

Fluke 1777 Power Quality Analyser

- Two-in-one PQA and PQ meter

- Easy-to-use, streamlined interface

- Automatic measurement capture

- Captures over 500 power quality parameters

- Measures harmonics, dips, swells, unbalance, voltage, current, and power

- High-speed transient capture up to ±8kV

- Transient capture sample rate: 1MS/s and 20 MS/s

- PQ meter function

- Large, bright touchscreen display

- Navigation buttons

- Guided setups

- Create custom views

- USB interface

- Wi-Fi interface

- Transfer data without interrupting monitoring

- Compatible with Fluke Energy Analyse Plus Software

- One-click reporting function

- Can be powered directly from the measured circuit

Energy Consumption

Likewise, Fluke also suggests analysing and recording the load and energy consumption of assets such as:

- Machinery

- Lighting

- Air conditioning

- Ventilation

- Heating

Recommend Product: Fluke 1732/1734 Three-Phase Electrical Energy Logger

Fluke 1732 Three-phase Electrical Energy Logger

- Suitable for load studies, energy assessments, energy surveys, and assessing operating conditions

- Measures and logs critical data

- RMS voltage: up to 1000V

- Current: up to 1500A

- Active power, reactive power, and power factor

- Active and reactive energy

- Store over 20 logging sessions

- View results in real time

- Guided graphical setup screens

- Intelligent connection verification

- Bright, full-colour touchscreen

- Upgradeable design

- Supplied with Fluke Energy Analyse Plus Software

Fluke 1734 Three-phase Electrical Energy Logger

- Suitable for load studies, energy assessments, energy surveys, assessing operating conditions, power and energy logging, and simplified load studies

- Measures and logs critical data

- RMS voltage: up to 1000V

- Current: up to 1500A

- Voltage and current THD

- Active power, reactive power, and power factor

- Active and reactive energy

- Store over 20 logging sessions

- Log over a year's worth of measurements

- View results in real time

- Guided graphical setup screens

- Intelligent connection verification

- Bright, full-colour touchscreen

- Upgradeable design

- Supplied with Fluke Energy Analyse Plus Software

- Fluke Connect enabled

Energy Waste

Excessive heat may indicate wasted energy due to poor insulation, electrical faults, or mechanical failings. To combat this, Fluke recommends scanning your facility for areas of intense heat.

Recommended Product: Fluke TiS55+/TiS75+/Ti300+ Thermal Camera

- IR resolution: 256 x 192px

- Thermal sensitivity: 40mk

- Temperature range: -20°C to +550°C

- Accuracy: ±2°C/ 2%

- Frame rate: 9Hz

- FOV: 28° x 20°

- Minimum focus distance: 0.5m

- Manual and fixed focus

- IP54

- 2m drop tested

- 3.5" VGA touchscreen LCD

- 6 thermal colour palettes

- Colour alarms

- PIP mode

- Voice annotations

- IR-PhotoNotes

- Fluke Connect enabled

- Asset tagging

- IR resolution: 384 x 288px

- Thermal sensitivity: 40mk

- Temperature range: -50°C to +550°C

- Accuracy: ±2°C/ 2%

- Frame rate: 9Hz or 27Hz

- FOV: 42° x 30°

- Minimum focus distance: 0.5m

- Manual and fixed focus

- IP54

- 2m drop tested

- 3.5" VGA touchscreen LCD

- 6 thermal colour palettes

- Colour alarms

- PIP mode

- Measurement tools

- Dew point colour alarm

- Voice annotations

- IR-PhotoNotes

- Fluke Connect enabled

- Asset tagging

- IR resolution: 320 x 240px

- Thermal sensitivity: 75mk

- Temperature range: -20°C to +650°C

- Accuracy: ±2°C/ 2%

- Frame rate: 9Hz or 60Hz

- FOV: 34° x 24°

- Minimum focus distance: 15cm

- Automatic and manual focus

- IP54

- 2m drop tested

- 3.5" touchscreen

- IR-Fusion technology

- LaserSharp auto focus

- Laser distance meter

- Voice annotations

- IR-PhotoNotes

- Fluke Connect enabled

- Supplied with Fluke Connect Desktop Software

Air Leaks

As previously established compressed air leaks can be a costly drain on energy. This is also true of vacuum and steam installations. Scanning systems to spot these invisible leaks can provide significant energy and economic savings.

Recommended Product: Fluke ii900 Acoustic Imager

- Frequency Range: 2kHz - 52kHz

- Detection Distance: 50m

- LeakQ mode

- 7" LCD touchscreen display

- SoundSight technology

- Multiple microphones

- Improves user safety

- Efficiently inspect an entire plant

- Easy to use

- Carry out inspections during peak operating times

- Detect leaks in compressed air, gas, steam, and vacuum systems

Further Information

For additional details on any of Fluke’s six essential tools for energy management, please don’t hesitate to contact our Sales team on 01642 931 329 or via our online form.

Download Fluke’s Paper on The Best Tools for Energy Management & Sustainable Maintenance

Alternatively, information about all of Fluke’s products can be found on our website.

[1] Chauvin Arnoux, Sound Advice on Saving Energy, last accessed 20 February 2024.

[2] Chauvin Arnoux, Monitoring your way to higher profits, last accessed 20 February 2024.

[3]As estimated on Wednesday 14th February 2024 using Google’s currency converter.

[4] Fluke, Hidden profits found in quick detection of compressed air, gas and vacuum leaks, last accessed 20 February 2024.

[5] Chauvin Arnoux, Sound Advice on Saving Energy.

SECR regulations apply to companies with:

- 250+ employees

- A turnover greater than £36m

- An annual balance sheet of more than £18m

[6] Chris Coath, ‘Digital Maintenance’, FMJ, 31.1 (2023), 30-31, at p. 30.